The following attributes are common to all Willowbrook Park hangars:

- Ground Lease: Each hangar has separate ground lease with the airport authority

- Door Engineering Hangar Doors: Premier solid tip-up canopy door, except Hangar 1, which has a bottom rolling door

- AmbiRad Infrared Heating System: Highly efficient heating system

- Parking Area: No need to enter restricted area to park adjacent to or enter the hangar

- Metal Halide Overhead Lighting: Provides high luminous efficacy

- Vehicle Doors: Overhead with remote opener

- Restroom: Water closet, sink, 40 gal. water heater

- Electrical: Commercial three-phase service

- Standing Seam Roofing: Long life with little maintenance

- Post-Tensioned Concrete Floors: Reduces/eliminates shrinkage, cracking, movement

- Fire Alarm: Central Station Monitoring

- Clerestory Windows: High in the sidewalls; provides excellent natural light

- Personnel Doors: Two with exterior lighting and exit lights/markings

- Vinyl Covered Insulation: High R-value on all walls, ceiling and hangar door

- Sprinkler System: Water

- Steel Framework: Painted with high-gloss white

- Exterior Floodlights: High intensity lights on timer switches

Door Engineering Hangar Doors

The hangar doors are Tip-Up Canopy doors (except Hangar 1 which has a bottom rolling door) designed and manufactured by Door Engineering & Manufacturing, Inc.. This door system provides a weather-tight seal and maintains a quick, yet stable motion. Minimal side room requirements of the Tip-Up Canopy door allow for maximum access to the facility with the benefit of long-lasting dependability.

The one piece Tip-Up Canopy door system has multiple wire rope pick-up points attached to the front of the door framing that are run to the counterweight and floor mounted operator assembly. The wire rope provided has a minimum safety factor of 5:1 at each of the pick-up points.

The opening vertical rise movement is followed by a simultaneous tilting and rising motion to the horizontal full-open position, with the bottom portion of the door projecting outside to form a canopy.

Tip-Up Canopy doors clear an opening at a quick rate of speed. The high-speed operation of the Tip-Up Canopy door minimizes heating and cooling losses and reduces waiting time resulting in increased productivity and energy efficiency.

AmbiRad Infrared Radiant Heating

The infrared heating units are designed and manufactured by AmbiRad. The internal air temperature for radiant heated buildings may be lower than for a conventionally heated building to achieve the same level of body comfort, when adjusted so the perceived temperature is actually the same. One of the key advantages of radiant heating systems is a much decreased circulation of air inside the room and the corresponding spreading of airborne particles.

A gas fired infrared heating system emulates the efficiency of the sun. This method of heating allows the source of heat to begin at floor not ceiling level. Once the infrared energy is absorbed by floors, machinery, stock and people, it is re-radiated to warm the surrounding air. This makes it the most efficient and effective heating method for the diverse conditions present in warehouses, storerooms and other immense structures.

Metal Halide Overhead Lighting

Metal Halide Overhead Lighting

Metal Halide lamps have high luminous efficacy of around 75 – 100 lumens per watt, which is about twice that of mercury vapor lights and 3 to 5 times that of incandescent lights. Lamp life is 6,000 to 15,000 hours and produce an intense white light.

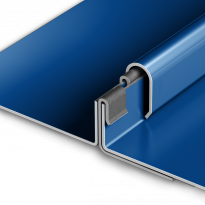

Standing Seam Roofing

Standing seam roofing is constructed out of lightweight sheets of metal that feature an outer layer of the corrosion-resistant material zinc. This type of roofing remains one of the strongest, most durable and longest-lasting types of roofing available to consumers.

Standing seam roofing is constructed out of lightweight sheets of metal that feature an outer layer of the corrosion-resistant material zinc. This type of roofing remains one of the strongest, most durable and longest-lasting types of roofing available to consumers.

This type of roofing is made out of interlocking metal panels that are crimped together on-site. Panels and seams run vertically from the top of the ridge down to the bottom of the roof. Seams are crimped in a fashion where they are raised to prevent water from seeping between them and to encourage efficient water run-off. Panels can flex at the seams to compensate for temperature change.

Standing seam roofing can be fabricated out of a number of metals like aluminum, steel and copper. This type of roofing can be difficult to puncture. Standing seam roofing will not promote mildew growth or mold growth and can last for more than 20 years with little maintenance.

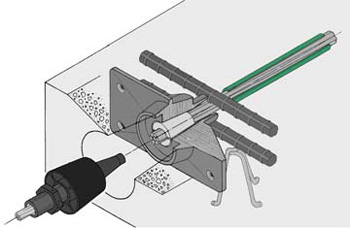

Post-Tensionioned Concrete Floors

Post-Tensionioned Concrete Floors

Post-tensioned concrete is the descriptive term for a method of applying compression after pouring concrete and the curing process. The concrete is cast around a plastic, steel or aluminum curved duct, to follow the area where otherwise tension would occur in the concrete element.

A set of tendons are fished through the duct and the concrete is poured. Once the concrete has hardened, the tendons are tensioned by hydraulic jacks that react (push) against the concrete member itself.

This method of reinforcing concrete enables a designer to take advantage of the considerable benefits provided by prestressed concrete while retaining the flexibility afforded by the cast-in-place method of building concrete structures.